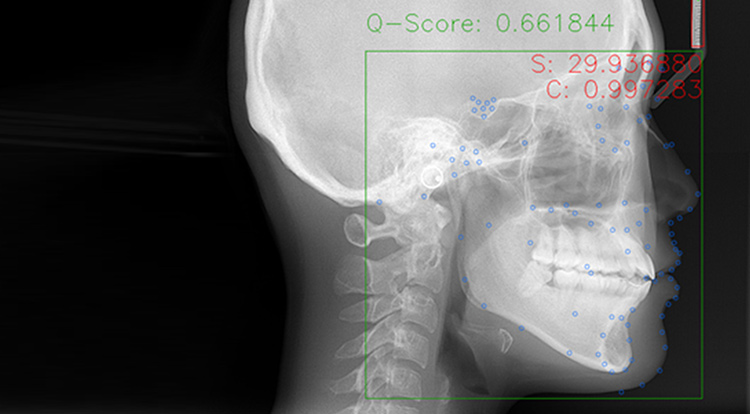

High-precision quality control of products in manufacturing

In manufacturing, quality control is a collaborative effort and a vital reflection of all production factors.

However, companies inevitably face the problem of standardizing quality control procedures. Plus, it can be challenging to standardize responses, either in the presence or absence of issues.

In cases when subjects of quality control have different or even unique features, it gets especially hard to identify and eliminate defects. Keeping these issues in mind, we offer our computer vision solution aimed at streamlining this process cost-effectively and with high precision.