How Video Camera System Can Help Companies in Manufacturing

Depending on the industry and working environment, there may be different requirements for workers to follow. For example, wearing personal protective equipment (PPE), HORECA uniforms, technical maintenance, hospital or laboratory clothes, emergency kit equipment or vehicle equipment.

However, it is hard to keep track of every worker and oversee whether they follow the rules. In order to avoid unfortunate consequences and penalties, digitally transform and automate the way you monitor what is happening within the company.

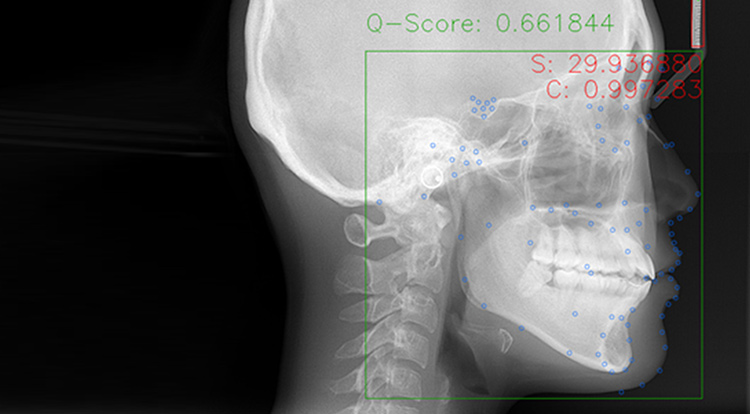

To help employers gain a clear understanding of the internal processes, CVisionLab’s solution utilized computer vision algorithms.

The method is based on deep neural network capabilities for image pattern recognition. This allowed us to spot workers violating health and industrial safety regulations. However, the scope of application extends to many other areas.